Treating water of river Ganga

Providing clean drinkable water to vicinity

System Advance Technologies Pvt. Ltd. is specialized in execution of turnkey project work and undertakes job of design, integration and manufacturing of reliable useful product as per customer needs. The quality performance and user-friendly operation during execution of jobs are the motto of the organization

Results

-

Reliable system in place, with almost negligible maintenance involved in automation process.

Providing drinkable water to more than 3000 people daily.

Turbidity sensor has been working over 5 years now for this location without any failure.

The capacity of water plant is 8MLD and the process is to retrieve water from the river Ganga and store it in a manmade pond inside the WTP for further treatment of water to make it drinkable. The clean and safe treated water distributed to school, colleges, and hospital, residential complex, mess and dining hall serving to more than 5000 devotees on daily basis.

Customer challenge

Providing clean water for drinking to the premises of Rama Krishna Mission and Math was first objective of the customer and they were looking for a reliable partner who can provide the solution for water treatment plant, with continuous online measurement, available 24x7.

System advance technologies were appointed by PHED Kolkata to install, commission, run and maintain the water treatment plant at Belur, Howrah in 2011, situated on the banks of the river Ganga.

Raw water to Clariflocculator via flash mixer, an electromagnetic flow meter was installed at the inlet of Stilling Well to measure the quantity of raw water intake. The pH, turbidity of the raw water was measured to check the quality of water received from the river. The gate was automated to open, based on di erential water level of the river Ganga and pond.

Our solution

Our solutions were integrated with the complete processing of the raw water. Our objective was to provide the best fit solution for each stage of the process, which can optimize the process and deliver a reliable latest measurement system.

Sluice gate of water intake channel control water entry from river to pond was done through motor operated Sluice Gate automation based on level measurement. The system use to draw water to internal pond during high tides.

The treatment process involves pre and post chemical treatment of raw water and quality check is the most important parameter in a treatment process. We implemented reliable measurement of pH, turbidity and residual chlorine in the clear water.

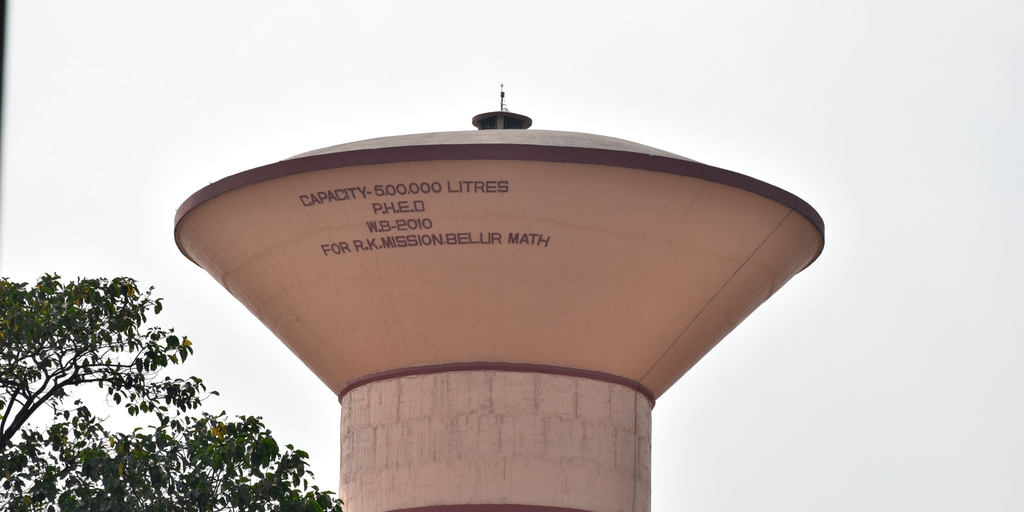

Overhead reservoir, the elevated reservoir storing the treated water with capacity of 5,00,000 liters established in the initial phase of the project.

A flow meter was installed at outlet delivery pipe line to measure the quantity of clear water delivered and level measurement was used to automate the clear water pump operation to li the water to overhead reservoir from ground reservoir with the capacity of 600 C.U.M.

Clean water reservoir, processed water will get be stored in the reservoir, before sending to nearby locality.