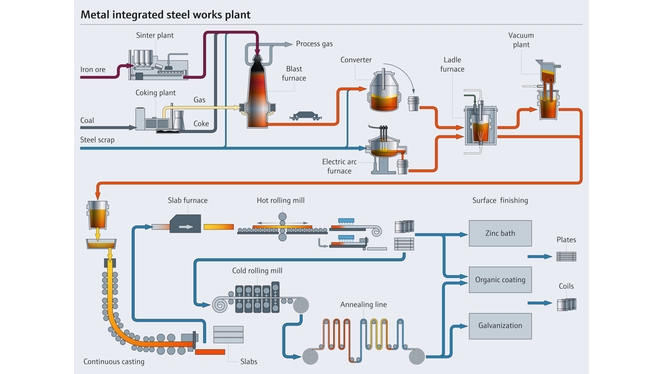

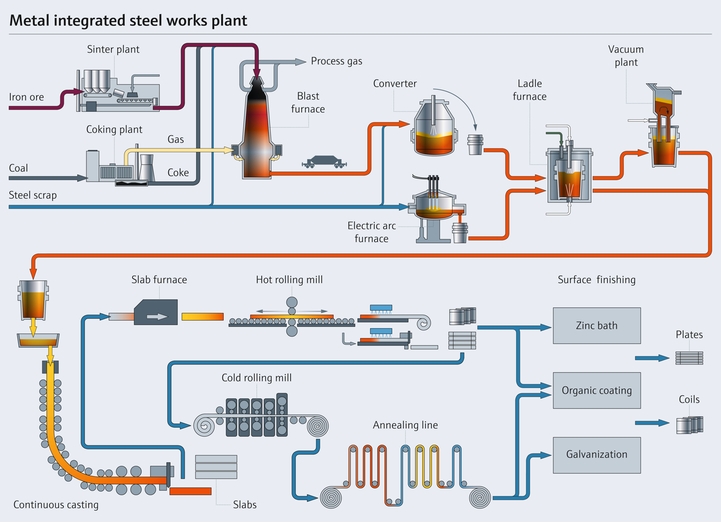

With the steel markets being highly competitive cost-efficiency is one of the top priorities for plant managers. And as energy costs can constitute up to 40 % of the overall costs, energy consumption has a huge potential for cost optimization. Think for example of utilities, or “W.A.G.E.S.” (water, air, gas, electricity, steam). Utility costs in the steelmaking industry are equal to more than 3% of a plant’s revenue in the United States, and more than 6% of revenue in Europe.

Key facts

Up to 40%

of the overall steel production costs are spent on energy according to the World Steel Association.

Find out how you can optimize your costs

W.A.G.E.S. management

W.A.G.E.S. (Water, Air, Gas, Electricity, Steam) all play an important role in steel production. The steam, which is generated from water, is used as an energy source. So, naturally W.A.G.E.S. provide a huge potential for optimization by closely monitoring production and consumption.

Our expertise in the field

Endress+Hauser offers a complete portfolio of different measuring technologies for parameters like flow, pressure, level and temperature we can offer integrated solutions to increase W.A.G.E.S. efficiency. We have shown that a return of investment can be achieved within two years.

- Our flow and energy manager calculates standard volume as well as mass and energy flows of natural and technical gases, fluids and steam from flow, pressure, temperature and density.

- Pressure plays a crucial role in steam generation. Our sensor is designed according to IEC 61508 for use in SIL2/3 safety systems.

- Measuring the level in the boiler ensures a consistent steam generation.

- Our modular temperature sensor feature all common communication protocols - including Bluetooth® technology.

Level measurement in the blast furnace

The profiles of the coke, iron ore, limestone and additives are important. For charging purposes it is essential that the axially symmetric bulk goods process is monitored when filling when with a rotating chute and that its positioning is controlled.

Our expertise in the field

To control the stacking, the profile of the surface is analyzed by up to five level instruments..

- We recommend using 80Ghz radar level sensors

Controlling annealing furnace gases

Plates and coils harden and temper in continuous annealing furnaces. The process needs to be monitored not only to ensure product quality, but also to optimize energy consumption.

Our expertise in the field

The first parameter for controlling the operation of the burner heads is naturally temperature. Another key component for an ideal combustion is the right supply of pressured air and mixed gas.

That’s why pressure must also be monitored.

- This temperature sensors is desgined for measuring points with extremely high process temperatures.

- Our pressure sensor guarantees high degree of system safety thanks to vacuum-proof ceramic membrane with integrated breakage detection.

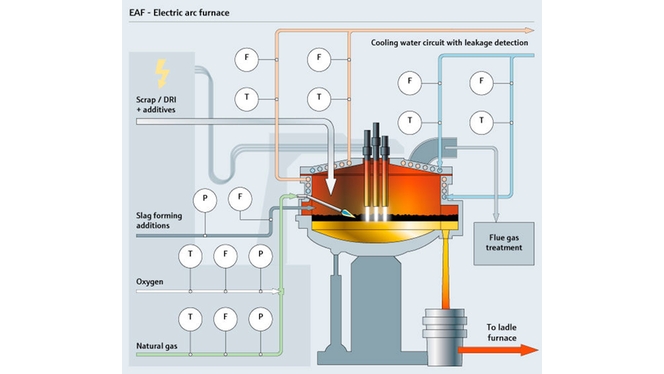

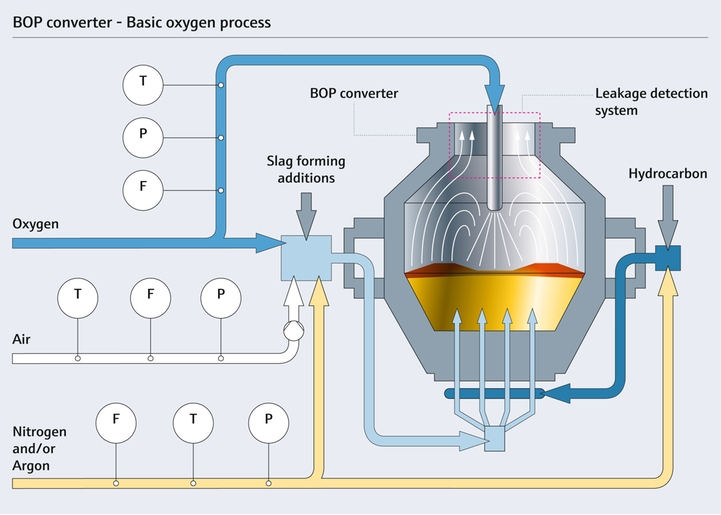

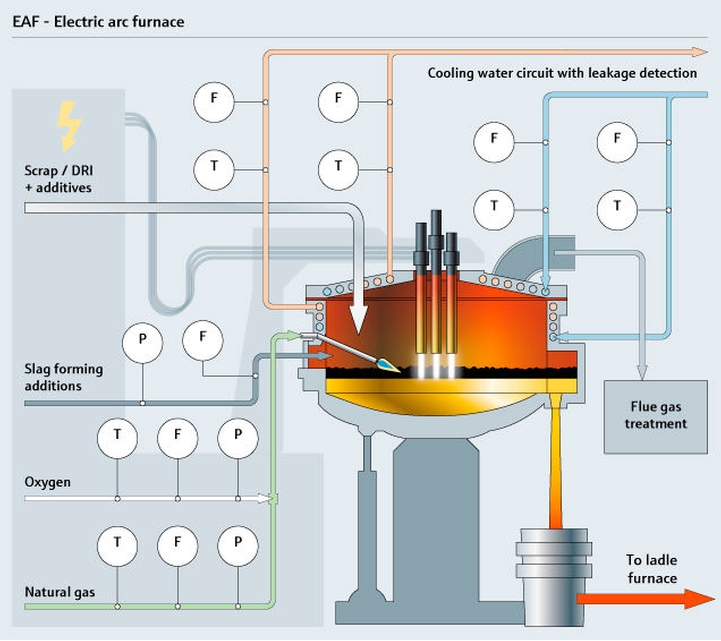

Electric arc furnace optimization

The electric arc furnace (EAF) is the heart of electric steel-making, where electrical energy is used to melt the main feed materials, solid scrap and/or direct reduced iron (DRI).

Our expertise in the field

For optimizing process reliability, flow, pressure and temperature sensors play an important part. They perform their tasks dependably in the tough, hot environment and assist with leak detection of compressed air and the control and analysis of argon and nitrogen, natural gas, oxygen and water. Robust and reliable field instruments help to improve efficiency of the energy input into the furnace.

- Depending whether you want to measure oxygen or other natural gases, we either recommend using a coriolis flowmeter or a thermal flowmeter.

Acid density measurement in cold rolling mill

Concentrated hydrochloric acid is used to to clean mill scale from steel plates in cold rolling mills. As the acid is constantly reused, it gets contaminated by iron chloride and deposits on the plates. This can result in the acid becoming over concentrated or crystallizing.

Our expertise in the field

By measuring the conductivity of the acid, the concentration is determinated and if necessary, the addition of rinse water can be prompted. Installing the measuring inline saves time and money. In addition, there is no longer any need to transport aggressive and toxic media to the lab, which means reduced health risks for operators.

- With this conductivity sensor you benefit from high chemical resistance and long durability thanks to robust materials (PFA, PEEK).

Benefits

Endress+Hauser offers a complete range of process instrumentation as well as dedicated automation solutions and comprehensive services that support the entire life cycle of your steel plant. Thanks to over 60 years of industry experience in even the most challenging environments, employees can make valuable recommendations on how how best to combine smart measurement sensors to reduce energy consumption and save money.

Key facts

33%

of the costs for pressured air can be saved using our smart instrumentation and solutions.

Key facts

1-2 years

does it take approximately for our steam monitoring solution to pay off thanks to reduced energy costs.

Key facts

55,000

smart sensors integrated in 65 digital optimization projects.

How we can help

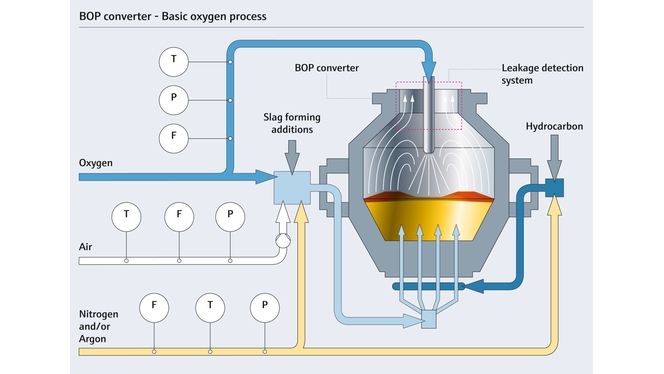

To improve the performance of a blast furnace, a converter or an electric arc furnace, various critical parameters have to be closely monitored. Having reliable and accurate measurements ensures a tighter process control and by that an optimized energy usage. Also critical is the optimal usage of argon, compressed air or steam. As they have a direct impact on the result of the process they also influence how much energy is used.

- W.A.G.E.S. management

- Level measurements in the blast furnace

- Controlling annealing furnace gases

- Electric arc furnace optimization

- Acid density measurement in cold rolling mill