Inline monitoring of ketchup quality and teamwork pays off

Block and release under control thanks to innovative measuring technology

The consistency of each ketchup batch before release has to be rigorously measured. Thanks to inline viscosity measurement the quality control can be done continuously during production, saving time waiting for lab results. This ensures production within specifications from the beginning, avoiding product losses and therefore reducing unplanned costs.

The results

The producer implemented Promass I in the ketchup line and can monitor the product quality in real time. The investment in such quality control has a potential ROI of 1 year with economic benefits in raw materials, energy, labor and recall costs.

The producer is able to reduce the number of non-conformities by reliable continuous and real-time quality control.

The operator now has the necessary information to react quickly to quality variations without waiting for the lab results.

The company now plans to implement this technology and the acquired know-how into their other sauce lines.

The challenge

The food producer strives for consistent quality in ketchup production, achieved by high standards in hygienic production practices and strict quality control. Most important is the measurement of ketchup consistency. This is done in the lab, taking a sample for each batch. Products that don’t meet the specifications are blocked.

Besides the lab measurement, the producer wanted an inline viscometer to provide continuous and real-time quality control, enabling fast reaction to non-conformities.

Our solution

Ketchup is a non-Newtonian Thixotropic fluid, its viscosity changes with shear rate and time. This brings a real challenge when in-line viscosity reading and lab results need to be correlated. Therefore, the process influence factors have to be considered when comparing two product quality measuring methods.

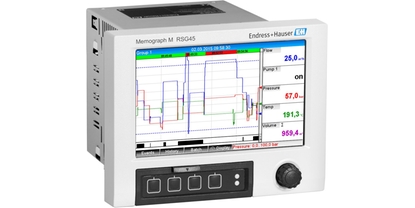

A team with experts from both companies cooperated on a test program using the Coriolis flowmeter Proline Promass I for in-line viscosity measurement and the data manager Memograph RSG45.

Proline Promass I viscosity meter

The straight single-tube design of Proline Promass I provides in-line viscosity measurement in addition to mass flow, density and temperature measurement.

Torsional oscillation of the measuring tube creates a shear rate of the fluid. Shear force on the inside of the tube is a function of shear rate and viscosity. Shear force defines the necessary drive power. Through measurement of the damping on the tube, the required drive power and hence the viscosity can be calculated.

Heartbeat Technology

Heartbeat Technology guarantees permanent diagnostics and verification of Promass I without process interruptions.

In this project the permanent self-diagnostics has enabled the recognition of unreliable data due to unpredictable process changes. The self-verification and the trend recognition for predictive maintenance have allowed further process optimization.

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |